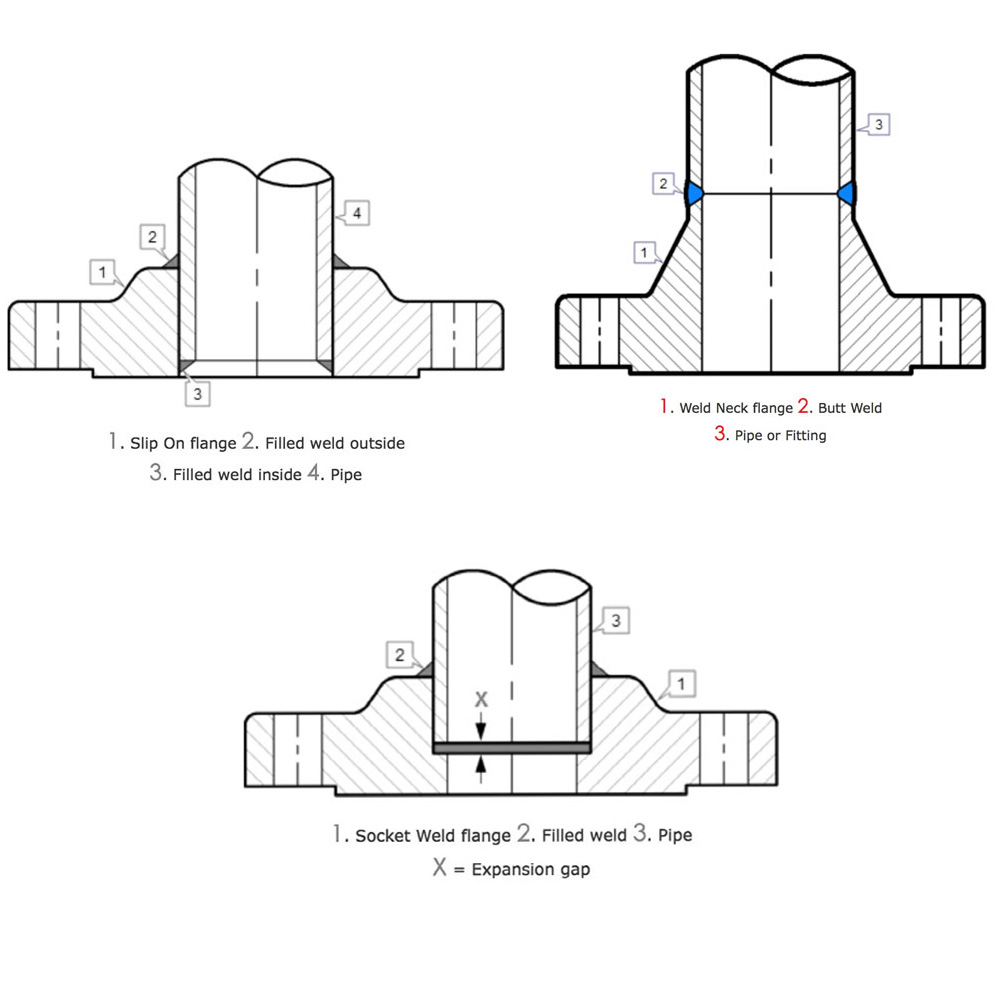

1.Flat welding, butt welding a me socket welding flange

ʻO ka hoʻoheheʻe ʻana o ka paipu i ke ʻano o ke kuʻi palahalaha, ka kuʻekuʻe kuʻekuʻe a me ka flange wiliwili kumu

Hoʻokomo maʻamau ka wili socket i ka paipu i loko o kaflangeno ka wiliwili ana.ʻO ka hoʻoheheʻe ʻana ʻo ia ka hoʻoheheʻe ʻana i ka paipu a me ka ʻili o ke kīpuʻu welding flange, ʻAʻole hiki ke hana i ka ʻike ʻana o ka ray ma ka weld socket, akā hiki ke hana ʻia ka wili ʻana.

2. Nui nā ʻokoʻa a me nā noi

ʻO ka maʻamau, ʻoi aku ka kiʻekiʻe o nā koi o ka welding butt ma mua o ka socket welding, a ʻoi aku ka maikaʻi ma hope o ka welding, akā ʻoi aku ka paʻakikī o ka ʻike.ʻO ke kuʻi ʻana no ka ʻike ʻana i ka hala o ka ray, ka wiliwili kumu e hana ai i ka pauka magnetic a i ʻole ka hoʻāʻo ʻana i ke komo ʻana (e like me ke kila kalapona i ka pauka magnetic, ke kila kuhili ʻole ke komo).Inā ʻaʻole pono ka wai i loko o ka pipeline i ka wili kiʻekiʻe, pono ia e hoʻohana i ka socket welding no ka ʻike kūpono.

Hoʻohana ʻia ka hapa nui o nā ʻano pili o ka socket welding i nā valve liʻiliʻi anawaena a me nā pipeline, nā paipu paipu a me ka wili pipeline.ʻO nā paipu anawaena liʻiliʻi he lahilahi i ka mānoanoa o ka paia, maʻalahi ke kuhi hewa ʻole a hoʻopau ʻia, a paʻakikī ke wili, no laila ua kūpono lākou no ka wili kumu.Eia kekahi, ʻo ke kumu o ka welding socket he hopena hoʻoikaika, no laila hoʻohana ʻia ma lalo o ke kaomi kiʻekiʻe.Eia nō naʻe, loaʻa nō hoʻi nā pōʻino ʻole o ka welding socket.ʻO kekahi, ʻaʻole maikaʻi ke kūlana koʻikoʻi ma hope o ke kuʻi ʻana, a ua maʻalahi ke hoʻokō ʻole i ke komo ʻana o ka welding.Aia nā āpau i ka ʻōnaehana paipu.No laila, ʻaʻole kūpono ka wili socket no ka ʻōnaehana paipu i hoʻohana ʻia no ka crevice corrosion sensitive medium a me ka ʻōnaehana paipu me nā koi maʻemaʻe kiʻekiʻe.Eia kekahi, ʻo nā pipelines ultra-kiʻekiʻe, ʻoiai inā he nui ka mānoanoa o ka pā o nā pipeline liʻiliʻi-diameter, hiki ke hoʻopili ʻia i ka pilina e like me ka hiki ke pale i ke kumu kuʻi.

I ka pōkole, hana ʻia ka welding socket i ka weld fillet, aʻo ka welding butt e hana i ka weld butt.Mai ka nānā ʻana i ka ikaika a me ke koʻikoʻi o ka weld, ʻoi aku ka maikaʻi o ka hui pū ʻana ma mua o ka hui socket, no laila pono e hoʻohana ʻia ka hui pū i ke ʻano o ke kiʻekiʻe kiʻekiʻe a me ke kūlana lawelawe maikaʻi ʻole.

3. Koho flange

1.According i ka mea o ka pipeline e koho i ka maoli flange mea pono, e like me kuhiliʻole kila pipeline 'oiaʻiʻoʻaʻole iʻaeʻia e koho.flange kila kalapona ;

2. E like me ke anawaena inoa (DN) o ka pipeline a me ke kaomi inoa (PN) o ka pūnaewele pipeline holoʻokoʻa, ka'ākauflangekoho ʻia.I kēia manawa, ka honuaflange paipuhoʻohana maoli i ka ʻōnaehana maʻamau ʻAmelika a me ka ʻōnaehana maʻamau ʻEulopa;

3. E like me nā kūlana hana kiko'ī, ua kohoʻia keʻano o ka flange a me keʻano: e like me ke kuʻi paʻa me ka'ā'ī, ka loop flange, a me nā mea'ē aʻe, a me kaʻili o ka sila e hoʻokuʻuʻia, kahi mokulele piha, kahi concave a me ka convex surface, etc. .

No nā ʻāpana maʻamau ʻole, pono ia e hoʻolālā a hana e like me ke kaʻina hana hoʻolālā flange spec.

Ka manawa hoʻouna: Feb-20-2023